What

to look out for on your chosen weapon...  |

ON-OFF SWITCH: Must be clearly marked and functional. Watch out for some models

of saw where it's easy to switch off the saw by accident with your thumb when

tipping the saw on it's side. The chainsaw switch works by making a contact (a

normal switch breaks the contact), thereby short circuiting the ignition system.

This means that if the switch fails in use, then the saw will not switch off.

If this happens, the procedure is to apply the chain break and activate the choke,

this floods the saw and stops it.

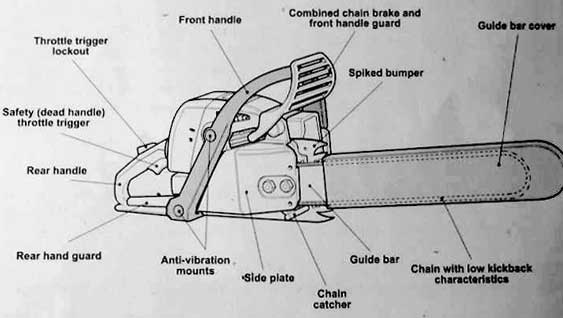

FRONT HAND GUARD /

CHAIN BRAKE: The front hand guard is absolutely essential and must be

in place on all chainsaws, even old ones. Only very old chainsaws come with a

front hand guard alone. All modern saws (that I'm aware of) have it combined with

a chain break mechanism that activates if the left hand (which grips the front

handle) hits, or pushes, the guard. This stops the chain within a fraction of

a second. With most saws it is also activated if the saw "kicks back"

whether the hand hits it or not. This is a very useful feature if you want to

avoid receiving a running chainsaw full in the face or through the shoulder in

the event of a snag and a "kickback".

CHAIN

CATCHER: A little tab below the guide bar on the body of the saw. It's

designed to catch the chain and prevent it from being thrown off the saw in the

event of a breakage. It also reduces the amount that the chain can whip back under

the saw possibly hitting the operator on the right hand, leg or crotch. It's also

worth mentioning that you should not point a working chainsaw at anyone nearby

(the nearest anyone should be is 5 metres), if the chain does get thrown off it

may hit someone, it could be travelling up to 50 mph.

SAFETY

THROTTLE: The throttle trigger is designed to lock off if a hand is not

firmly grasping the rear handle (dead mans handle). This prevents twigs etc. from

activating the throttle whilst the saw is being carried when switched on.

CHAIN BREAKAGE GUARD: A protective flange on the rear handle protecting

the operators right hand from being hit by a broken chain whipping under the saw.

ANTI-VIBRATION MOUNTS: These mounts isolate the engine

part of the saw from the handles, considerably reducing the amount of vibration

transmitted to the operators hands (wearing the gloves reduces the vibration further).

This is very important to reduce the likelihood of the operator developing damage

to the circulation in his/her fingers (white finger syndrome). The mounts are

made of steel springs or rubber. The rubber ones are prone to perishing due to

the effects of fuel and oil and must be checked and replaced quite regularly.

If any of the mounts fail, the saw will flop about loosely in the handles and

will transmit a lot of vibration to the user. Very old saws may not have these

features and are likely to cause the operator a lot of discomfort. The operator

is also likely to be storing up lots of health problems for the future.

SILENCER: This must direct the exhaust fumes away from the operator.

Invariably directed into the exhaust airflow from the engine cooling fan. On top

handled saws it is directed backwards and to the right. With rear handled saws

it's usually directed forwards to the right, over the top of the guide bar and

chain. The silencer must be kept in good order, not only to reduce noise, but

also to reduce the likelihood of the operator breathing in exhaust fumes.

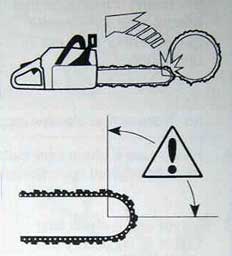

GUIDE BAR AND CHAIN: First the guide bar. Your guide

bar may be solid nose or sprocket nose, but in order to reduce any "kickback"

to a minimum it should be as small a radius as you can find for your saw. This

reduces the area in which the chain digs in if touching an obstacle. The danger

area is the front, top third of the nose of the bar. The chain should be chosen

with anti-kickback features in mind (most chains sold in Britain for hand held

chainsaws come with this feature as standard). The anti-kickback feature is normally

a long ramp of some sort that helps the chain feed smoothly into the wood - e.g.

Bumper drive links; Ramped depth gauges; Bumper tie straps (not shown).

|

|  |

Kickback

area of Guide Bar

| Anti-Kickback

features of Chain

| CHAIN

COVER: A plastic guard is normally supplied

for this purpose. It is an inexpensive piece of kit to replace and should be in

place whenever the saw is not being used. More cuts are suffered from unprotected

stationary chains than from moving ones. Homemade plywood guards and old wellies

can be used by the miserly.

STICKERS:

Strangely enough these are a legal requirement

in UK. The saw must carry head, ear, eye defender symbols on a sticker attached

to the saw. There is no prohibition on lightning or flame "boy racer"

type symbols on the saw (unlike that for the helmet).

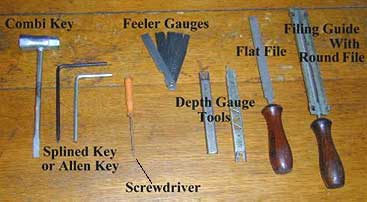

TOOLKIT: Unfortunately most saws seem to

come with only one combination key as the toolkit. This is woefully inadequate.

The operator should have the full toolkit required for regular, general maintenance

of the chainsaw. The full tool kit complement can be found by reading the chainsaw

owners manual for the make of saw. If you've bought your saw second hand then

find the dealer for that particular make and order a copy, then read it from cover

to cover at least 500 times.

A

standard tool kit usually comprises of: Combination side case/plug spanner come

screwdriver (combi key); Allen key or splined screwdriver (for other screws);

Small screwdriver (for idle adjustment); Feeler gauges (for sparkplug); Bar groove

cleaner (with pointy bit for poking dirt out of oil holes); Depth gauge setting

tool (to set the height of the depth gauges on the cutters); Small flat file (for

filing down depth gauges and removing burrs plus dressing guide bars); Appropriate

round chainsaw file complete with the proper filing guide for the sharpening of

the chain supplied with the chainsaw. |

So there's quite a lot

more than you might expect. We're not dealing with just another power tool.

|

| |